With epoxy and other polymer coatings, there is always the question of whether the concrete has been properly prepared. Is the surface rough enough to allow the coating to soak in and bond with the concrete? Is it too rough so that the ending surface is not the desired or specified texture?

The Basics

The Basics

The foundation for the success of floor coatings depends on whether the concrete has the proper concrete surface profile (CSP) or surface roughness to allow the coatings to properly adhere/bond to it. Concrete surface profiles are graded on a scale of 1 through 9 and generally correspond to the method used in the preparation of the surface. The International Concrete Repair Institute (ICRI) designates the CSPs in the ICRI Guideline No. 310.2R-2003, Selecting and Specifying Concrete Surface Preparation for Sealers, Coatings, Polymer Overlays, and Concrete Repair.

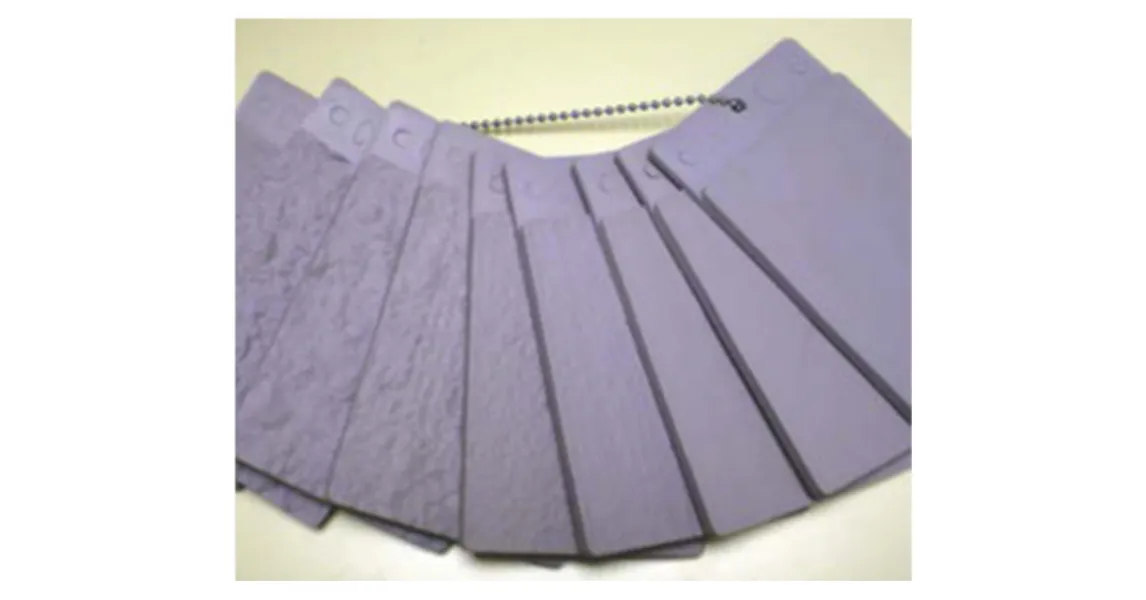

ICRI produces a set of CSP "coupons" that replicate each of the 9 profiles, which we use to train and measure.

Let’s take a look at these 9 profiles and discuss how they apply to the types of decorative and protective coatings installed by STRONGHOLD FLOORS (SF).

Concrete Surface Profiles (CSP)

| |

CSP 1 CSP 1

- Typical of acid-etch, low-pressure water cleaning, or grinding with finer tooling (40 grit or higher).

- Appropriate for use with acrylic or other low solids sealers.

- SF: We utilize this CSP only with sealers and very thin-mil, clear systems (such as a low-viscosity epoxy primer and urethane top coat).

|

|

|

CSP 2 CSP 2

- Typical of mechanical diamond grinding with 16 or 25 grit tooling.

- Appropriate for use with thin-mil and high build coatings.

- May require the use of low-viscosity primers.

- SF: We utilize this CSP for most residential projects (garage floors and basements) as well as commercial and light industrial floor coatings.

|

|

|

CSP 3 CSP 3

- Typical of a light shot blast (sometimes referred to as a “brush blast”).

- Appropriate for use with coatings with over 60 MILS (dry film thickness) of build.

- Not appropriate for thinner coatings such as solid color or metallic epoxy coatings.

- SF: We utilize this CSP when needing to remove contaminated surfaces and coatings with over 60 MILS DFT.

|

|

|

CSP 4 CSP 4

- Typical of a medium shot blast or light scarifying.

- Appropriate for use with thicker coatings and overlays, including double broadcast quartz coatings.

- SF: We utilize this CSP with self-leveling epoxy or urethane overlays.

|

|

|

CSP 5 CSP 5

- Typical of a medium-heavy shot blast, needle scaling, or scarifying.

- Appropriate for use with thicker coatings and overlays.

- SF: We utilize this CSP only with aggregate filled epoxy or urethane overlays.

|

|

|

CSP 6 CSP 6

- Typical of a heavy shot blast, needle scaling, or scarifying.

- Appropriate for use with thicker coatings and overlays.

- Used to remove contaminants, very thick overlays, or loose concrete

- SF: We do not utilize this CSP.

|

|

|

CSP 7 CSP 7

- Typical of a heavy shot blast, needle scaling, or scabbling.

- Appropriate for use with coatings and overlays more than 1/4" thick.

- Used to remove contaminants, very thick overlays, or loose concrete.

- SF: We do not utilize this CSP.

|

|

|

CSP 8 CSP 8

- Typical of an extreme shot blast, needle scaling, or scabbling.

- Appropriate for use with overlays more than 1/4" thick or re-decking with more concrete or blacktop.

- Used to remove contaminants, very thick overlays, or loose concrete.

- SF: We do not utilize this CSP.

|

|

|

CSP 9 CSP 9

- Typical of scabbling, rotomilling, ultra-high pressure water-jetting, or flame blasting.

- Appropriate for use with re-decking the concrete slab with another concrete pour.

- SF: We do not utilize this CSP.

|

Beyond the CSP

For more information on concrete surface preparation, check out the following blog posts:

Think you're ready to begin a floor coatings project? Request a free quote today by filling out this form!

Mike Mincemoyer is the President of STRONGHOLD FLOORS. Mike has been actively involved since the beginning in 2004. His formal floor coatings background includes training from PremierGarage, Crown Polymers, HTC America, SIKA, AmeriPolish, SASE, Metzger McGuire, L&M Chemical Company, and FGS/Permashine.

The Basics

The Basics

CSP 1

CSP 1 CSP 2

CSP 2 CSP 3

CSP 3 CSP 4

CSP 4 CSP 5

CSP 5 CSP 6

CSP 6 CSP 7

CSP 7 CSP 8

CSP 8 CSP 9

CSP 9