“A house is only as strong as its foundation.”

“A house is only as strong as its foundation.”

It’s a quote we've all heard at one time or another. Its core idea is very appropriate to epoxy floor coatings. Regardless of whether it’s a professional, like us, installing a commercial grade polymer or a homeowner installing an epoxy paint kit on their garage floor, the success of either is entirely dependent on the foundation. In this case, the foundation is the preparation of the concrete slab.

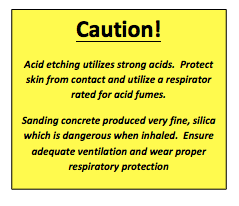

Whether the concrete is new or decades old, the longevity of any coating system begins with the preparation of the concrete surface prior to the application of the actual chemicals. Many methods exist to prepare concrete for a coating. For the "Do-It-Yourselfer", the typical method is acid etching or sanding. For the professional floor coatings installer, mechanical diamond grinding or shot blasting is the norm.

DIY Methods – Acid Etching & Sanding

Acid etching is a common technique included in DIY kits, but it lacks the ability to properly prepare tightly troweled surfaces (or sealed surface). It also cannot remove many of the substances that have already tarnished your concrete – such as existing paint, concrete sealers, motor oil, or other contaminants. All of these substances will decrease or even remove the ability for the DIY coating to adhere to the concrete.

Acid etching is a common technique included in DIY kits, but it lacks the ability to properly prepare tightly troweled surfaces (or sealed surface). It also cannot remove many of the substances that have already tarnished your concrete – such as existing paint, concrete sealers, motor oil, or other contaminants. All of these substances will decrease or even remove the ability for the DIY coating to adhere to the concrete.

Sanding is similar to the diamond grinding method, but floor sanders lack the ability to adequately open the pores of the concrete and can't create a deep enough abrasion pattern (called a Concrete Surface Profile or CSP; a CSP-2 or more is required for topical coatings). Again, the coatings then cannot soak in or lock onto the “foundation” properly.

As a result, the homeowner will quickly notice “pox” marks or chips in their newly coated surface – many of which could've been prevented by properly preparing the concrete.

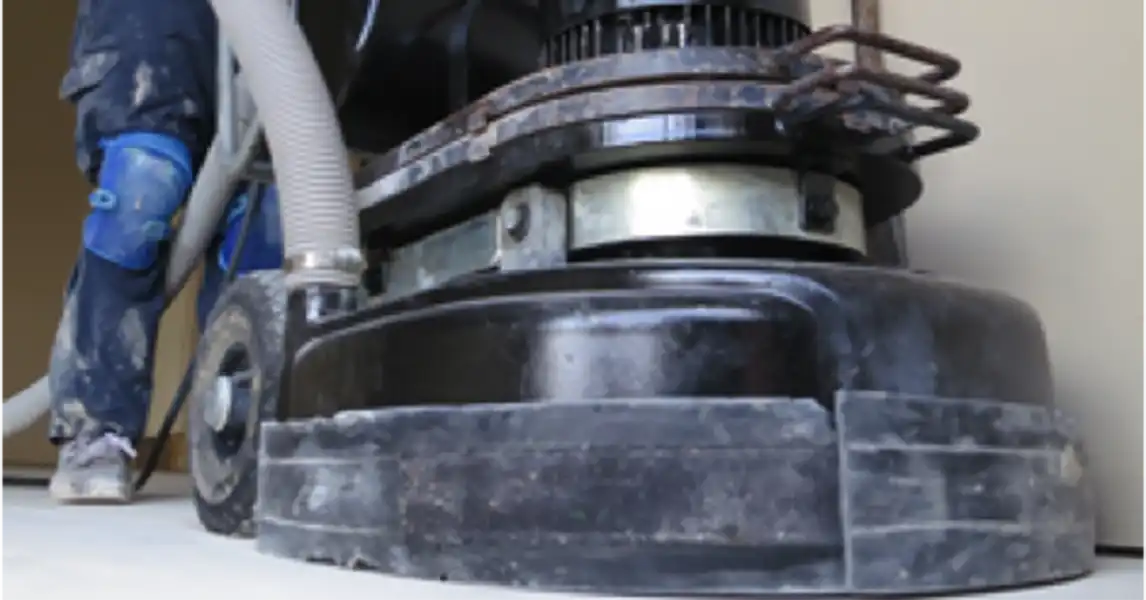

Professional Method – Planetary Diamond Grinding & Shot-Blasting

Conversely, the preparation of your concrete floor by a professional is going to be much more thorough. Professional coatings installers have the tools to get it done right, creating a concrete surface profile that ensures the coating will actually adhere to the floor. In fact, the coating’s bond should be so strong to the concrete that if you pull hard enough on the coating, the concrete should break away!

A professional will use a mechanical preparation method, such as diamond grinding or abrasive blasting. This opens the top surface of the concrete floor – removing any substances or sealants – and makes the concrete porous again. This process allows the coating to properly bond to the concrete and not simply lay over the top of it.

At the beginning of our coatings process, we utilize planetary diamond grinders with HEPA filtered vacuums so that the dust and any contaminants are contained and don’t become airborne. Our prep work also includes filling in any cracks and fixing any areas that need addressed. Only on rare occasions do we utilize our shot blaster, as that method is normally overkill for residential and commercial projects that are receiving a decorative coating.

At the beginning of our coatings process, we utilize planetary diamond grinders with HEPA filtered vacuums so that the dust and any contaminants are contained and don’t become airborne. Our prep work also includes filling in any cracks and fixing any areas that need addressed. Only on rare occasions do we utilize our shot blaster, as that method is normally overkill for residential and commercial projects that are receiving a decorative coating.

Granted, a homeowner or general contractor can rent grinders. Nearly all rental grinders are single or dual-disc machines that utilize block-style diamonds. These types of grinders are inferior to the more expensive planetary grinders which feature three floating heads and industrial diamond sets. In addition, some rental grinders are gas powered (vs our 22v electric powered grinders), which can posed the risk of carbon monoxide poisoning if there is not adequate airflow.

Single and dual-disc grinders do not create a uniformly prepared surface as quickly or as easily as a planetary grinder. Our company has five of these planetary grinders for garage and commercial floor preparation.

Building on the Foundation

Once proper surface preparation is complete, it’s time to move on to the installation of a high quality, commercial grade coating system. Read Materials & Maintenance of Garage Floor Coatings: DIY vs Professional to learn about the differences in materials and maintenance between DIY and professional floor coatings.

Once proper surface preparation is complete, it’s time to move on to the installation of a high quality, commercial grade coating system. Read Materials & Maintenance of Garage Floor Coatings: DIY vs Professional to learn about the differences in materials and maintenance between DIY and professional floor coatings.

Here are some additional, helpful articles:

- What Makes a Professional Garage Floor Coating Last?

- 5 Things to Consider Before You DIY Concrete Floor Coatings

- Epoxy Floor Coatings: 10 Tips for New Construction of Concrete Floors

As Founder & President of STRONGHOLD FLOORS, Mike works with his teams and sales partners in Maryland, Pennsylvania, and Virginia, providing both great coatings and coatings education to the residential & commercial public.

Editors Notes:

Major updates and republished in 2020.

LAST UPDATED: Sep 16, 2025