Concrete Coating System Selection

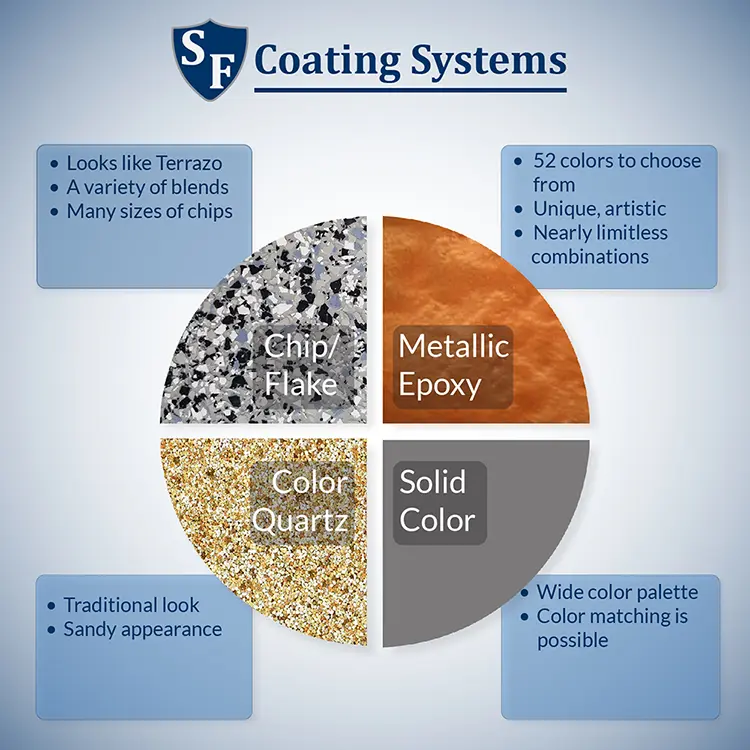

STRONGHOLD FLOORS recommends all our customers to determine their objectives first, then to contact us to discuss which concrete floor coating systems are appropriate for their goals. The systems shown in the diagram below are the most common coatings we offer, but they're not the only options.

While "epoxy" is the term most commonly used, often the correct coating systems combine epoxy base coats with polyaspartic, polyurethane, or polyurea top coats. The use and maintenance of the floor will often dictate which chemicals are appropriate. Our team can guide you through selecting the ideal flooring system for your concrete.

Each system may be composed of numerous layers of chemicals and media.

For more information on selecting the right concrete coating system, check out our four part blog series: Garage Floor Coatings Criteria.

Concrete Floor Coating Systems Offered by STRONGHOLD FLOORS

To learn more about each system, click on the image or the system name.

Transparent, minimal-profile coatings for concrete surfaces.

See Clear, Thin-Mil >

A decorative concrete system with textured, slip-resistant finishes.

See Decorative Chip/Flake >

Ideal for environments sensitive to static discharge.

See Electro-static Dissipating (ESD) >

Protects against moisture vapor emissions from concrete slabs.

See Epoxy Vapor Barrier >

Great for substrates with movement or cracks.

See Flexible Membrane >

Eye-catching finishes that mimic natural stone or abstract patterns.

See Metallic Epoxy >

High-strength urethane mortar coatings for industrial use.

See Mortar Systems >

For harsh chemical exposure areas like service bays.s.

See Novolac Epoxy/Chemical Containment >

Simple, clean solid epoxy coating options.

See Solid Color >

Combines color and texture for a durable, attractive finish.

See Decorative Colored Quartz >

Frequently Asked Questions about Floor Coatings

Generally speaking, a floor coating is one or more layers of a polymer coating. The polymer can be epoxy, urethane, polyurea, acrylic, MMA, or other formulations. Most floor coatings for residential or commercial will be epoxy, urethane, polyurea, or some combination of these.

Floor coatings may be poured and rolled, sprayed, or trowel-down. These installed methods are based upon the physical properties and applied thicknesses of the floor coating materials.

Floor coatings have distinct advantages over carpet, VCT, ceramic tile, hardwood, or linoleum/sheet goods. These advantages include:

- Not stained by splash spills.

- No grout to maintain.

- Greater impact resistance.

- Ease of cleaning.

- Lower maintenance.

- Renewable.

The longevity of any floor coating system will depend upon a number of factors, such as:

- Type of system installed.

- Type of normal wear and tear.

- Chemical and UV exposure.

- Type and frequency of cleaning.

Our staff will assist you with proper floor coating system selection.

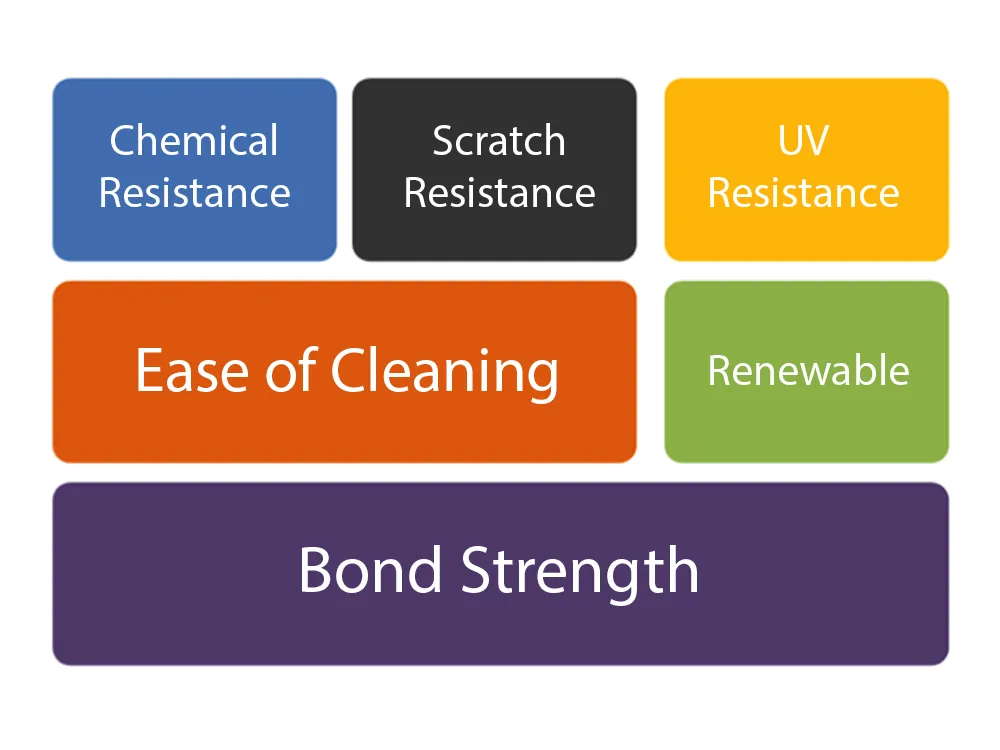

Not at all. All of our floor coating systems are commercial/industrial grade materials designed to be applied by professional floor coating companies. Their superior performance is based upon the materials themselves, the proper surface preparation, and adherence to installing under the proper conditions.

The epoxy paint kits or garage floor paint kits are essentially glorified latex or enamel paints. These paint or epoxy kits lack the bonding strength, UV resistance, chemical resistance, abrasion/impact resistance, and overall durability of our coatings.

Ask any co-worker, friend, or neighbor who has applied one of the "Do-It-Yourself" epoxy paint kits how it has held up to hot tires or daily use. You'll quickly learn why homeowners, builders, and companies turn to STRONGHOLD FLOORS for their floor coating needs.

Nope! The age of the concrete doesn't matter. Our floor coating projects have included concrete slabs dating back to the early 1900s!

Softer or porous concrete may require additional coatings layers or a primer. Heavily damaged slabs may require a skim coat or other more involved type of repair.

Our staff will conduct a site survey and design a coating system that is appropriate for your concrete slab.

While the exact amount of time varies based upon concrete mix construction, time of year, and curing conditions, the general rule of thumb is 28 days from date of pour.

We can assist with a more definitive answer. It's possible to reduce the curing time by making changes to the concrete mix design.

Some coatings manufacturers or installation companies may say it's possible. Our belief is "Do it right the first time." Why take a chance for the coatings to delaminate?

Our staff will prepare the concrete floor correctly. This involves removing all mastics and glue prior to installation of the first layer of coatings.

For residential floor coatings, most only require periodic dust broom or vacuum and the occasional mopping. Mopping may consist of only hot water or hot water coupled with a low/no suds cleaner (such as clear ammonia).

Commercial and industrial uses will vary greatly. Some of our customers follow the same regiment as a residential customer. Some have the need to clean daily with walk-behind or ride-on auto-scrubbers.

STRONGHOLD FLOORS will assist with determining a cleaning/maintenance schedule that's right for you. In the meantime, check out our blog post: 12 Tips for Use & Care of Your Epoxy Floor Coatings.