In the first part of this series, Garage Floor Coatings Criteria Part 1: Evaluating the Current Floor Condition, we reviewed the different problem conditions that may apply to your floor and their impact. No garage floor coating works well if the surface is not in good condition or prepared back into good, structural condition before the coatings are applied.

In the first part of this series, Garage Floor Coatings Criteria Part 1: Evaluating the Current Floor Condition, we reviewed the different problem conditions that may apply to your floor and their impact. No garage floor coating works well if the surface is not in good condition or prepared back into good, structural condition before the coatings are applied.

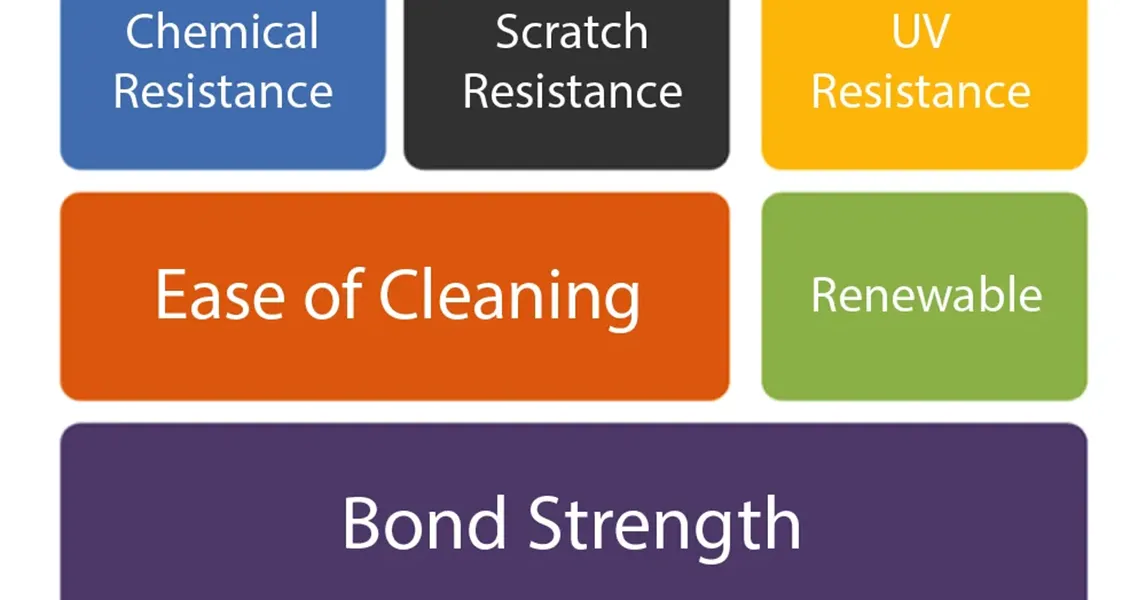

In the second article of this series, STRONGHOLD FLOORS discusses the performance requirements a homeowner should consider for a garage floor coating. Many of these characteristics are where the big box store’s garage floor paint or DIY epoxy kits fall short (see: Skip the Paint Kit & Frustration).

Let’s dive into each characteristic and why it matters.

STEP TWO: Determine the Coatings Performance Requirements

Chemical Resistance

Garage floors are typically exposed to more harmful chemicals than other floors in a residential home. The concrete is subjected to splash spills of gasoline, oil, car cleaning products, fertilizers, and snow/ice melt chemicals.

Professionally installed garage floor coatings systems should have some sort of resistance to harmful chemicals typically found in garages.

As concrete is naturally high in pH, it is subject to attack from any materials that are acidic. Over time, acids “etch” the surface of the concrete and decrease the durability of the wear surface.

A garage floor coating system should have topical layers that are designed to withstand short or long term exposure to a variety of chemicals. The coating system should be unaffected by chemicals used for winter road treatment. It should also be able to tolerate the intermittent exposures to weak acids, petroleum based substances, and liquids which contain solvents.

UV Resistance

Garages may or may not have windows, but they often have a fair amount of lighting installed. A good floor coating system must be able to withstand periodic exposure to ultraviolet (UV) light.

Most epoxies don't have high UV resistance, which is why most decorative floor coatings make use of urethane or polyuria based technologies, as these chemicals have UV inhibitors or are UV stable (do not yellow from exposure).

Scratch Resistance

A garage floor coating takes a lot of abuse from vehicle traffic. Small stones and grit on the tires comes in contact with the top of the coatings. Snow melt off introduces debris that can be repeatedly driven over until removed. These contacts can de-gloss or abrade the surface, causing it to look worn or damaged.

Much like the UV resistance, higher scratch (abrasion) resistance is normally achieved with the use of polyaspartics, urethanes, or polyurea based technologies found in our top coats.

Ease of Cleaning

Coating systems can have different textures that greatly impact the ease of cleaning. Most garage coating systems can just be swept free of debris and kept shiny with an occasional mopping.

Coating systems can have different textures that greatly impact the ease of cleaning. Most garage coating systems can just be swept free of debris and kept shiny with an occasional mopping.

Spilled liquids can easily be wiped up on any sealed system.

Some newer systems, such as Nature Stone® that promote that they “eliminate standing water and puddling” by letting the water flow down into them don't accurately describe their cleaning requirements. If liquids and small debris get into those systems, they can clog the pores, leading to offensive odors or potentially staining the system. These systems often require much greater amounts of cleaning effort than advertised.

For information on how to clean a floor coatings system installed by STRONGHOLD FLOORS, read the article 12 Tips for Use & Care of Your Epoxy Floor Coatings.

Renewable

No coating lasts forever. But unlike paints, most professionally installed garage coating systems have a thick enough top layer of the coatings to allow them to be mechanically abraded (sanded). Once properly prepared, a new protective layer of coating can be applied to the existing system.

While the need for this rejuvenation may not occur for several years, once it is needed, it won't require the large investment of replacing the entire system (which is more typical of DIY kits and garage floor paints).

Professionally installed garage floor coatings only need their top layer replaced if the floor needs to be "rejuvenated" after many years.

Bond Strength

Paints and poor quality, epoxy coatings often peel off the garage floor where the tires come into contact. This peeling (or delamination) is due to poor bond strength.

Garage floor coatings must adhere to the concrete and each layer of the coatings must adhere to each other ("inter-coat" adhesion) with a strength that exceeds the adhesive pull from hot tires.

The bond strength of a garage floor coating is also dependent upon the floor surface being properly prepared prior to the coatings application (see: How We Prep Before Epoxy Floor Coatings for how STRONGHOLD FLOORS prepares concrete).

While there are many ways to “prepare” the concrete surface, the process used must ensure that it adequately removes loose materials, imparts a sufficient concrete surface profile (CSP 2 or better), and opens the pores of the concrete.

CSP 2 (shown above) is the surface profile required for most of our garage floor coatings.

Step Two Conclusions

For a garage floor coating to perform well, it has to provide a lot of performance characteristics that are typically only found in professionally installed coatings. There are some garage coatings kits that exhibit these characteristics, but these kits are still subject to failure due to inadequate surface preparation. Check out 5 Things to Consider Before You DIY Concrete Floor Coatings for more information on DIY kits and their pitfalls.

The Next Step

This is the second of four articles dealing with garage floor coatings and their selection criteria. The series continues with Part III: Choosing the Desired Look.

The team at STRONGHOLD FLOORS has installed over 4,500 garage floor coatings in Maryland, Pennsylvania, Virginia, and Washington D.C. We install garage floor coatings that are tailored to provide the best balance of the characteristics discussed in this article. We believe in “Do it Right ALL the Time!”